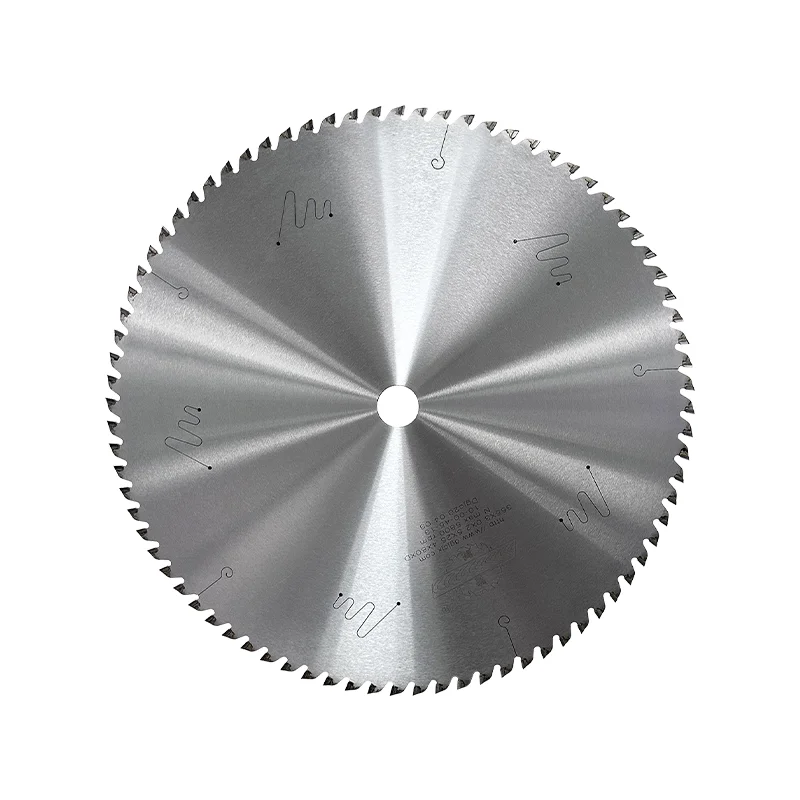

In many industrial fields such as metal processing, wood cutting, and plastic cutting, tungsten carbide circular saw blades have become an indispensable tool for many manufacturers due to their excellent characteristics such as high hardness, strong wear resistance, and long service life. With the continuous improvement of the industry's requirements for cutting efficiency and precision, more and more customers are no longer satisfied with general specifications of tungsten carbide circular saw blades, but hope to be able to order in bulk and OEM customization to meet personalized processing needs.

So, can tungsten carbide circular saw blades support bulk purchases and OEM customization? What technical details should be paid attention to during the customization process? What core indicators should be paid attention to when choosing an OEM manufacturer? This article will give you a comprehensive analysis.

1. Does tungsten carbide circular saw blade support bulk ordering?

The answer is yes, tungsten carbide circular saw blades fully support bulk purchases, and many factories prefer to accept bulk orders.

Suppliers have a mature production system

Many tungsten carbide circular saw blade manufacturers have automated CNC processing equipment and batch production capabilities, which can meet various procurement needs from small batch trial orders to large-scale industrial use. Whether you are a hardware processing plant, a furniture manufacturing company, or a metal building materials company, you can get more cost-effective products through bulk purchases.

The advantages of bulk ordering are obvious

More favorable prices: Most manufacturers will give step-by-step price discounts for bulk orders, and the purchase cost is lower.

Controllable delivery cycle: Through planned production, large-volume shipments can be completed within the scheduled time.

Strong product consistency: Bulk production makes it easier to ensure the consistency of product quality and performance, and reduce errors and defective product rates.

Support customized packaging: Bulk purchases can usually support additional customized services such as corporate brand LOGO packaging, labels, barcodes, etc.

2. Does tungsten carbide circular saw blade support OEM customization?

Tungsten carbide circular saw blades not only support bulk purchases, but also widely support OEM (original equipment manufacturing) customization services. The significance of OEM customization is that customers can personalize the specifications, structure, logos, etc. of the product according to their own processing equipment, application fields, brand style and other needs, so as to achieve product differentiation competition.

2.1 What does OEM customization include?

The OEM customization service of tungsten carbide circular saw blades mainly covers the following aspects:

Specification and size customization

Outer diameter (such as: 110mm, 180mm, 255mm, 350mm, etc.)

Inner hole diameter (adapt to different sawing machine axes)

Number of teeth (customized according to cutting material requirements, such as 48 teeth, 60 teeth, 100 teeth, etc.)

Saw blade thickness (common such as 1.2mm, 1.8mm, 2.4mm, etc.)

Tooth structure customization

Flat teeth, staggered teeth, ladder flat teeth, high and low teeth, etc.

Angle adjustment: main deflection angle, secondary deflection angle, etc.

Cut head material optional (such as carbide or special coating)

Coating and treatment customization

Surface coating (TiN, TiCN, TiAlN, etc.) enhances wear resistance and oxidation resistance

Shock absorption groove design (reduces noise and cutting vibration)

Packaging and LOGO customization

OEM customers can provide brand LOGO for laser engraving of saw blade body or outer packaging printing

Customizable color box, blister shell, carton, display packaging with hanging holes, etc.

3. Why more and more companies choose OEM to customize tungsten carbide circular saw blades?

OEM customized tungsten carbide circular saw blades have become an important choice for many brands and processing companies. The reasons behind this are mainly as follows:

3.1 Improve market competitiveness

By customizing saw blades with exclusive parameters, processing efficiency and cutting quality can be significantly improved, making the product more advantageous.

3.2 Brand building

OEM products with LOGO and personalized packaging can enhance customers' memory of the brand, which is conducive to market promotion and long-term cooperation.

3.3 Reduce R&D costs

Enterprises do not need to build their own production lines, but only need to provide product specifications and brand requirements, and OEM manufacturers are responsible for the entire production process, reducing investment costs and technical risks.

3.4 Meet diverse needs

For different customer groups, such as high-end markets, mid-range retail or export trade, different series of tungsten carbide circular saw blade products can be customized separately.

4. What are the key points to pay attention to when customizing tungsten carbide circular saw blades?

Before OEM customization or bulk purchases, it is recommended to communicate with the manufacturer in detail from the following dimensions:

4.1 Clarify the usage scenario

Different application areas (such as wood, aluminum, stainless steel, plastic) correspond to different types of tooth shapes and materials, which need to be confirmed in advance.

4.2 Sample proofing stage

High-quality suppliers will make samples before mass production to ensure that product specifications and performance meet expectations.

4.3 Technical drawings and parameter standardization

If there are special design requirements, it is recommended to provide CAD drawings or technical specifications to avoid production errors.

4.4 Contract and after-sales guarantee

Ensure that a standardized OEM contract is signed, and the terms such as delivery date, payment, warranty, and after-sales are clearly stated to ensure procurement security.

5. How to choose a reliable OEM tungsten carbide circular saw blade manufacturer?

In China and Southeast Asia, there are many professional tungsten carbide circular saw blade manufacturers that provide OEM services. However, suppliers that are truly worthy of long-term cooperation usually have the following characteristics:

Quality certification systems such as ISO or SGS

Possess independent research and development and mold design capabilities

Stable production capacity and short delivery cycle

Support one-to-one customized services and technical consultation

Have rich export experience and be familiar with overseas market certification requirements

If you are an overseas buyer, you should also pay attention to whether the manufacturer has export qualifications, whether it can provide sea/air customs declaration information, and whether it supports multilingual communication.

Whether you are a small processing plant that has just entered the industry, or an industry distributor with an existing brand, choosing tungsten carbide circular saw blades that support bulk ordering and OEM customization can not only obtain more cost-effective products, but also open up a broader market space for your business.

Tungsten carbide circular saw blades are no longer just tools, but a strategic resource to improve efficiency, optimize costs, and enhance brand influence. It is time to cooperate with the right manufacturer to create your own tungsten carbide saw blade brand.

If you are looking for a tungsten carbide circular saw blade supplier that supports OEM customization and bulk ordering, please contact us for more product information, technical parameters or customized solution suggestions.

www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd.