https://www.ascendtechs.com/guangzhou-ascend-injection-pumps.html

As the mobile digital industry races toward the goals of high battery life, high safety and slim design, the steel-cased battery design adopted in Apple's new-generation devices optimizes internal structure and enhances energy density, delivering an unprecedented battery life experience to users. Guangzhou Ascend injection pump has long been the preferred supplier of liquid injection equipment in Apple's supply chain benefiting from core technologies such as high liquid injection precision and advanced vacuum liquid injection valves, which contributes to laying a solid foundation for the key technologies required for the large-scale production of steel-cased batteries.

Steel-Cased Batteries + Vacuum Injection: Apple Leads the Trend of Technological Innovation in the Industry

All models of Apple's new-generation devices are equipped with steel-cased batteries, and this design's advantages are fully reflected in:

Significantly improved space utilization rate: The steel-cased structure can adapt more flexibly to the internal space of the mobile phone, creating physical conditions for battery capacity expansion and providing users with longer-lasting battery life support.

Significantly optimized heat dissipation performance: The metal casing has excellent thermal conductivity, which can accelerate heat transfer, effectively reduce the negative impact of high temperatures on battery life and ensure that the battery maintains stable performance during long-term use.

Significantly enhanced safety: The steel-cased structure can effectively suppress battery swelling and reduce safety risks caused by mechanical damage, providing more reliable safety assurance for users' daily use.

However, the sealing performance and the internal space compactness of steel-cased batteries pose extremely strict challenges to the injection process. The traditional atmospheric pressure injection method is prone to problems such as residual air bubbles in the electrolyte and uneven wetting, which in turn lead to adverse consequences including battery capacity fading and shortened cycle life. Vacuum injection technology enables the electrolyte to quickly and evenly penetrate into the micro-pores of electrode sheets driven by pressure difference, making it an indispensable process for the mass production of steel-cased batteries.

Four Core Technologies Forge an Industry Benchmark in Vacuum Injection

Ultra-high vacuum injection control eliminates air bubble hazards

Equip ped with advanced high-vacuum injection needle valves, Guangzhou Ascend injection pumps can still ensure a stable and smooth injection process in a vacuum environment of -95kPa, eliminating dripping and leakage and guaranteeing no air bubbles are generated. This technology effectively enhances the cycling stability of batteries and provide reliable assurance for the long-term use of batteries.

±0.05% Ultra-Precision Injection Accuracy Fully Guarantees Battery Consistency

In a vacuum environment, the viscosity and fluidity of the electrolyte changing places more stringent requirements on the control of injection volume. Guangzhou Ascend injection pumps adopt a high-precision servo motor drive and a closed-loop feedback system, achieving ultra-precise control of the liquid injection volume with an accuracy of ±0.05%. This ensures the uniformity of the electrolyte in each steel-cased battery, significantly improves the yield rate of the production line, and lays a solid foundation for the high-quality production of Apple's batteries.

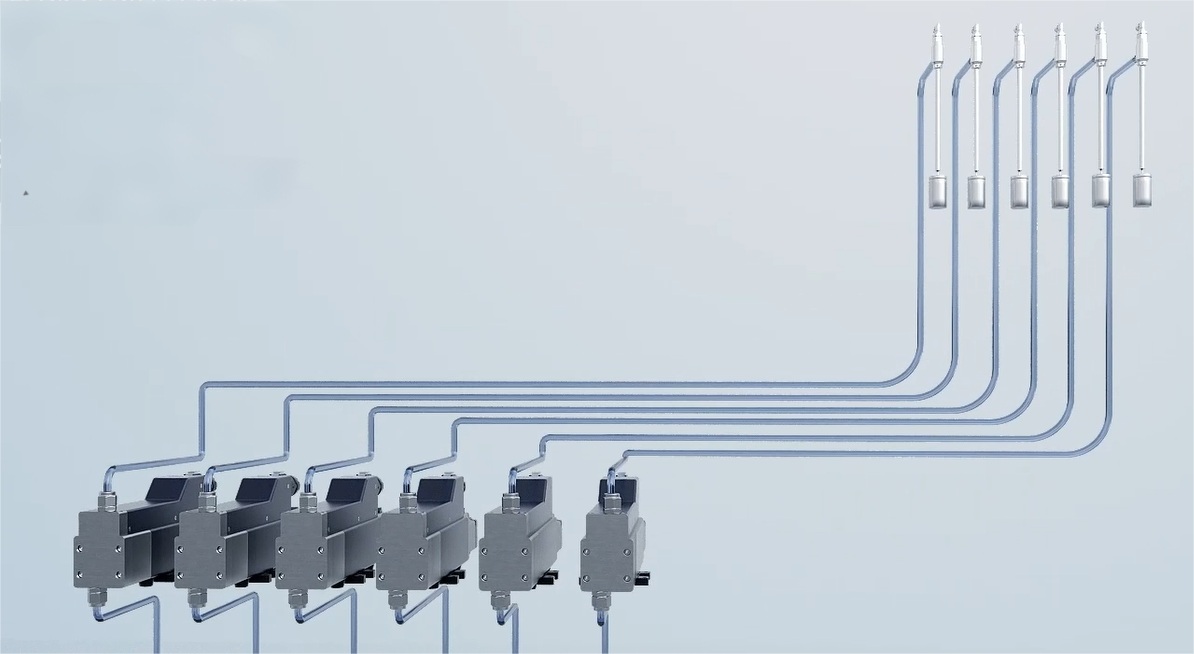

Multi-Channel Integrated Injection Significantly Improves Production Line Efficiency

In response to the demand for large-scale mass production of Apple's batteries, the LA Linear Injection Pump from Guangzhou Ascend demonstrates outstanding performance. It enables simultaneous use of multiple channels which greatly facilitates the integration of liquid injection machines, while helping to optimize the flow channels of liquid injection machines and effectively reducing electrolyte residue.

Diversified Adaptation System Meets Diverse Production Needs

Guangzhou Ascend injection pumps are available in a variety of specifications and suitable for different models of steel-cased batteries and diverse electrolyte characteristics, ensuring optimal injection results in various production scenarios. Whether it is dealing with electrolytes of different viscosities and corrosivities, or adapting to diverse material systems such as silicon-carbon anodes and high-nickel cathodes, it can handle them with ease, providing strong support for the diverse production needs of Apple's batteries.

Customer Testimonial: Dual Leap in Efficiency and Quality

Relying on its outstanding performance and reliable quality, Guangzhou Ascend's LA Linear Injection Pumps have not only become the preferred injection pump brand for ATL, but also widely served the digital soft-pack, cylindrical and steel-cased production lines of customers such as COSMX, Sunwoda, LG and Samsung, winning consistent praise from customers. The recognition from numerous customers fully demonstrates the significant advantages of Guangzhou Ascend injection pumps in improving production efficiency and ensuring product quality.

Unceasing Innovation, Jointly Embracing the New Future of Smart Terminals

In the face of technological challenges posed by next-generation technologies such as all-solid-state batteries, Guangzhou Ascend has made early arrangements, demonstrating strong technological foresight and innovation capabilities.

● Vacuum injection solution for semi-solid-state steel-cased batteries: In the field of semi-solid-state batteries, injection pumps need to support the injection of high-flow-rate and high-viscosity electrolytes. Guangzhou Ascend has a variety of advanced injection systems, which can meet the liquid injection/coating requirements for high-viscosity electrolytes (such as those containing LiFSI new lithium salts) and corrosive electrolytes. These systems are compatible with diverse material systems including silicon-carbon anodes and high-nickel cathodes, providing strong support for the R&D and production of semi-solid-state batteries.

Cooperate with Guangzhou Ascend to Seize the Technological High Ground in Smart Terminals

In the new innovation cycle, breakthroughs in battery technology have become a key battleground for competition in the smart terminal industry. With the core philosophy of "Vacuum Precision, High Efficiency & Stability, Intelligent Adaptation", Guangzhou Ascend injection pumps provide one-stop liquid injection solutions from R&D to mass production for global 3C electronics enterprises. Whether you aim to enhance the competitiveness of your existing steel-cased battery production lines or lay out the groundwork for next-generation battery technologies, Guangzhou Ascend will always be your most trustworthy partner.

https://www.ascendtechs.com/guangzhou-ascend-injection-pumps.html

Guangzhou Ascend Precision Machinery Co.,Ltd.