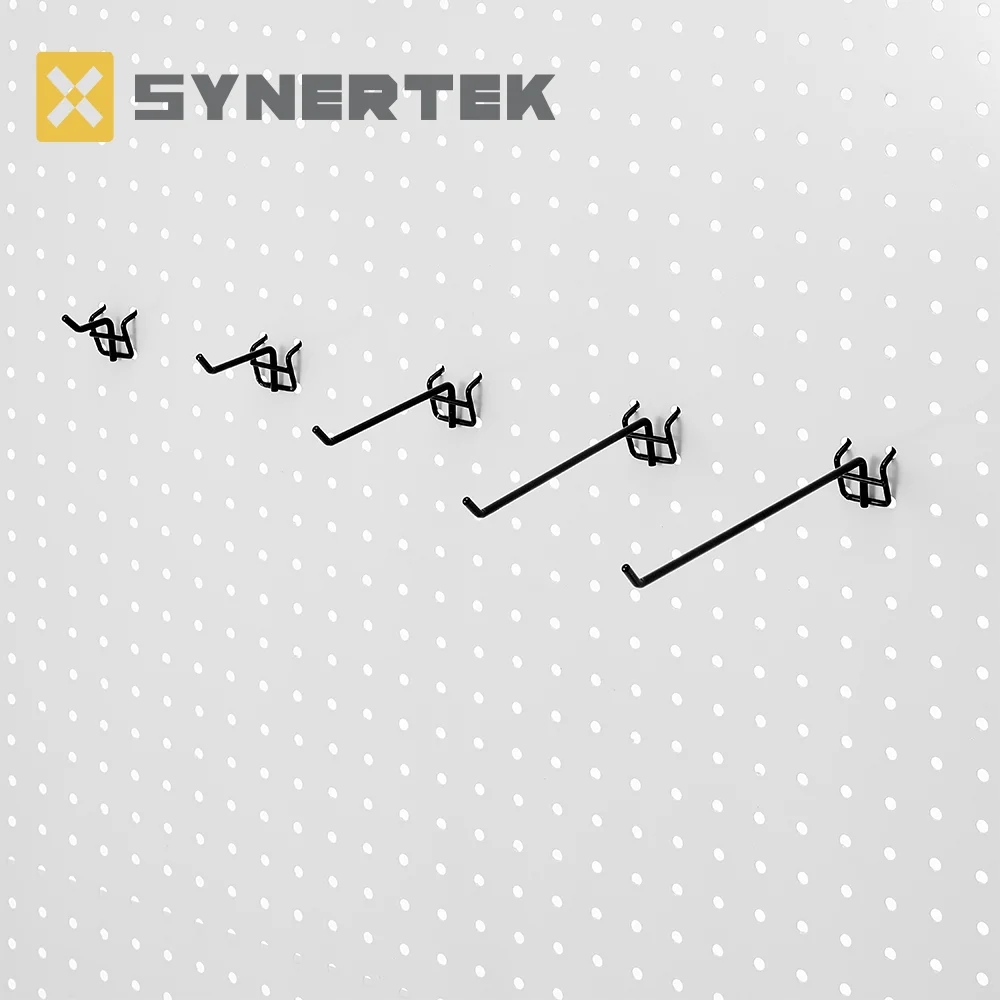

In a competitive retail environment, every detail matters. Most supermarket managers focus on sourcing better-selling products, optimizing store layouts, and improving customer service. Yet, one overlooked component directly affects sales performance: shelf hooks.

While simple in appearance, shelf hooks play a critical role in product accessibility, shelf organization, and visual merchandising. Poor hook designs reduce display efficiency, slow stocking times, and can frustrate customers trying to reach products.

This article explores the real value of upgrading shelf hooks, supported by industry experience from Suzhou Synertek Industry Products Co., Ltd., a company that has spent more than two decades designing and manufacturing metal display accessories for global clients.

The Unseen Problem: Display Inefficiency

Walk into any supermarket, and you will see rows of hooks supporting packaged food, household items, beverages, and impulse goods. Yet, not all hooks are created equal.

Common performance issues include:

-

Hooks bending under weight

-

Uneven surface coating that rusts or wears off

-

Inconsistent lengths affecting display alignment

-

Difficult installation, leading to time-consuming adjustments

-

Hooks sliding or tilting, causing product misplacement

When hooks fail in these ways, the problems compound:

-

Staff spend longer stocking and organising products

-

Items appear messy or unsafe, lowering customer trust

-

Inventory becomes harder to track visually

-

Fewer items fit on display per square meter

-

Products may fall, increasing loss and labor costs

A low-cost component ends up silently draining operational efficiency.

Why Small Hardware Generates Large Value

Shelving hardware impacts three measurable performance categories:

1. Display Density

High-quality hooks allow more products per facing. A better hook design increases the number of SKUs displayed without expanding shelf space. For high-volume categories like snack foods, beverages, and daily household items, denser displays generate greater return per square meter.

2. Product Accessibility

Ergonomically shaped hooks improve product removal. Customers should be able to grab items without struggling, tipping adjacent packages, or cutting their hands on rough edges.

3. Stocking Efficiency

Staff time spent restocking hooks, adjusting alignment, or replacing bent or damaged hooks adds up. With durable and precise metal hooks, turnover becomes faster and more predictable.

Upgrading these small metal accessories results in measurable operational improvements.

A Manufacturing Perspective: Why Quality Hooks Matter

Suzhou Synertek Industry Products Co., Ltd., established in 2004, has dedicated more than 20 years to hardware product manufacturing. Over that time, the company has observed a trend: retailers increasingly value quality in small display components as automated retail systems and precision merchandising become the norm.

Synertek operates a modern standardized facility exceeding 1000 square meters, equipped with complete production systems. Their professional technical team ensures high precision manufacturing and strict quality control throughout each stage. The combination of advanced equipment and skilled labor improves production efficiency, minimizes defect rates, and delivers consistent performance across batches.

Such foundations provide a competitive advantage: hooks are produced with exact dimension tolerances, uniform chrome finishing, smooth edges, and reliable load-bearing characteristics. These factors reduce maintenance, stocking errors, and wear over time.

Their products meet international client requirements, enabling Synertek to serve well-known global enterprises as a certified supplier. This level of control is critical for retailers who require predictable performance across thousands of display units.

Where Better Hooks Pay Off

Supermarkets implementing upgraded hook systems often report improvements in:

-

refresh rate of promotional item placement

-

visibility of hot-selling products

-

use of vertical display space

-

stocking labor redistribution

-

store aesthetics and brand perception

Consider a typical retail case: a supermarket chain upgrades to precision-engineered chrome metal hooks. After rollout, stocking teams gain an average of five minutes per aisle per shift, product alignment remains consistent, and promotional displays become easier to rotate. Over a large number of stores, such small increments represent substantial savings.

Innovation Over Tradition

Traditionally, supermarkets prioritised low-cost hooks, treating them as disposable components. But rising demand for operational reliability, cleaner stores, and modern display systems has shifted expectations. Supermarket operators now view hooks as part of integrated merchandising architecture rather than interchangeable hardware.

Suzhou Synertek actively embraces this shift. Instead of repeating traditional manufacturing approaches, the company invests in improved tooling, finishing processes, load testing, and modular display solutions. They evaluate real-world challenges, work with international clients to refine hook dimensions for specific shelving systems, and design hooks that balance durability with efficient production.

Supermarkets facing rapid product turnover, seasonal fluctuations, and diverse packaging shapes require adaptable hook systems. Precision manufacturing reduces the need for constant adjustment. Durable surface finishing prevents corrosion, ensuring long-term performance even in high-humidity areas such as beverage sections.

Below is a sample anchor link to a metal hook model frequently used in supermarket displays:

<a href="https://www.szxlqg.com/Supermarket-Shelf-Hooks-Small-Size-Products-Display-Chrome-Surface-Metal-Hook.html">Supermarket shelf display hooks</a>

Factors to Consider When Choosing Shelf Hooks

When evaluating suppliers and hook models, consider:

Material Quality

Stainless steel and plated metal resist corrosion and deformation. Poor-quality metal fatigues over repeated loads.

Surface Treatment

Uniform chrome coating prevents rust and complements store aesthetics. Surface polishing matters for customer safety.

Load Capacity

Not all hooks support equal weight. Evaluate expected product weight before deployment.

Dimensional Precision

Exact dimensions ensure compatibility with pegboards, perforated panels, wire grids, and gondola shelving.

Ease of Installation

Hooks should secure firmly without requiring tools or frequent realignment.

Manufacturer Capability

A technically capable manufacturer ensures consistent supply, repeatability, and reliable logistics. Synertek’s standardized production and strict quality control provide predictability, which is essential for chain-wide deployment.

Why Supply Chain Matters for Hooks

Supermarkets scaling operations often overlook supply chain risks for low-cost display components. But unpredictability leads to mismatched hook sizes or inconsistent finishes across locations. This disrupts visual uniformity and complicates maintenance inventories.

Partnering with experienced hardware manufacturers enables:

-

consistent production across batches

-

assured quality compliance

-

reduced risk of dimensional variations

-

controlled lead times

-

minimized defect-related replacement costs

Over 20 years of specialization positions Synertek to anticipate display challenges and adapt solutions for dynamic market demands.

A Shift Toward Holistic Display Efficiency

Supermarkets increasingly integrate data-driven merchandising with display hardware decisions. When hooks deliver predictable performance, display planning systems can calculate facing capacity accurately. This supports optimized planograms, smoother seasonal transitions, and precise product replenishment.

Shelf hooks may appear insignificant, but they anchor the structural foundation of retail presentation. Upgrade decisions compound across thousands of hooks, turning minor improvements into measurable profit gains.

Conclusion

Shelf hooks are more than functional accessories. They influence product visibility, stocking efficiency, inventory management, and store aesthetics. As supermarkets compete to increase margins and improve customer experiences, investing in durable, well-designed, precisely manufactured hooks becomes a rational operational strategy.

Suzhou Synertek Industry Products Co., Ltd. exemplifies how advanced manufacturing capabilities deliver real value to retailers. With modern facilities, strict quality systems, and over two decades of professional experience, the company demonstrates that even small hardware components deserve innovation.

Supermarkets willing to rethink traditional assumptions about hardware investment can unlock overlooked efficiencies and build a stronger competitive foundation in modern retail.

www.szxlqg.com

Suzhou Synertek Industry Products Co., Ltd.