In the high-pressure world of industrial manufacturing, precision and durability are non-negotiable. Whether you're pressing laminates, composite panels, wood, or advanced materials, the hot press plate plays a pivotal role in ensuring optimal results. CNC machined hot press plates have become a cornerstone of modern production lines, offering the precision, customization, and consistency required by today's industries. This article will guide you through what to consider when selecting the right CNC machined hot press plates and why your choice matters for performance, longevity, and efficiency.

What Are CNC Machined Hot Press Plates?

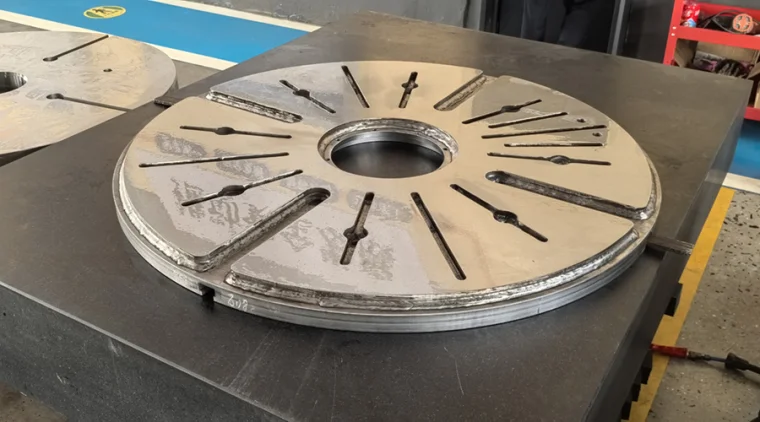

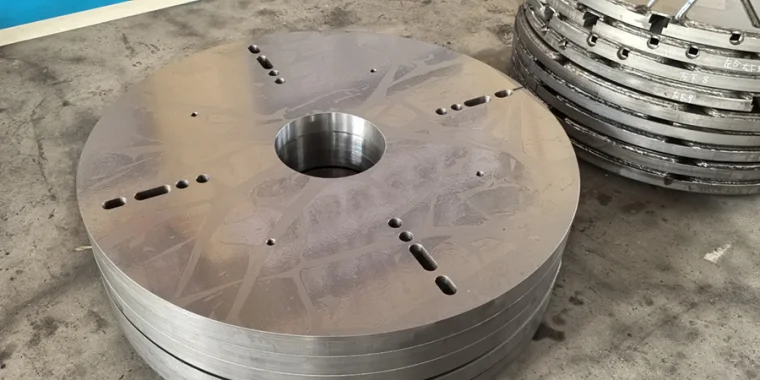

CNC (Computer Numerical Control) machining refers to the automated control of machining tools via a computer, allowing for incredibly accurate shaping of metal components. Hot press plates, which are used in high-temperature pressing applications, are typically crafted from carbon steel or stainless steel and rely on precision to ensure uniform pressure and heat distribution.

When these plates are CNC machined, the results are highly accurate dimensions, smoother finishes, and reduced variability between batches—ensuring reliability in heat transfer, structural performance, and product consistency.

The Role of Hot Press Plates in Manufacturing

Hot press plates are vital in various industries, such as:

1. Woodworking and Laminate Production: Used for producing plywood, veneer, and laminated boards.

2. Electronics and PCB Manufacturing: Assists in the lamination of printed circuit boards.

3. Composite and Thermoplastic Fabrication: Ensures uniform bonding under heat and pressure.

4. Rubber and Plastic Molding: Helps mold and shape materials with consistent surface finishes.

5. Regardless of the application, hot press plates must deliver uniform heat transfer, maintain shape under pressure, and resist warping over time. CNC machining enables these capabilities to be optimized.

Why CNC Machining Matters

Traditional manufacturing methods can't match the precision and repeatability of CNC machining. Here’s how CNC machining elevates hot press plate quality:

1. Enhanced Precision and Uniformity

CNC machining ensures that each plate meets exact dimensional tolerances. This is crucial in applications where even minor variations can lead to uneven pressure or temperature zones, resulting in product defects.

2. Customizability for Application-Specific Needs

Manufacturers can design CNC machined plates with grooves, channels, or surface treatments tailored to specific materials or thermal needs. This customization improves process efficiency and final product quality.

3. Superior Surface Finish

The smooth surface finish achieved through CNC machining reduces wear on pressing materials, improves thermal conductivity, and minimizes maintenance needs.

4. Consistent Reproducibility

Once a CNC machining program is created, it can be reused to produce identical plates, supporting scalable production and spare part reliability.

Key Factors to Consider When Choosing a CNC Machined Hot Press Plate

To select the best hot press plate for your needs, consider the following technical and operational criteria:

1. Material Composition

Different materials provide varying benefits:

Carbon Steel: Offers excellent strength and thermal conductivity at a lower cost.

Stainless Steel: Provides corrosion resistance and is ideal for high-moisture or clean-room environments.

The material choice will impact durability, maintenance requirements, and cost-effectiveness.

2. Plate Thickness and Size

The thickness should suit your press’s capacity and the temperature/pressure levels it must withstand. Plates must be machined to exact specifications to ensure a perfect fit in your machine’s press bed.

3. Thermal Performance

CNC machined plates can include built-in heating channels or be designed for use with external heating systems. Uniform temperature distribution is essential to avoid warping, delamination, or incomplete curing.

4. Pressure Resistance and Stability

High-pressure applications require plates with strong structural integrity. CNC machining enables internal stress relief processes, such as surface hardening or controlled finishing, to maintain flatness over time.

5. Surface Treatments and Coatings

Depending on the application, hot press plates may benefit from anti-stick coatings, surface hardening, or corrosion resistance treatments. These treatments prolong life and reduce maintenance needs.

Common Applications and Industry Use Cases

1. Wood-Based Panel Manufacturing

In this industry, CNC machined hot press plates are used to press particleboard, MDF, and plywood. Surface grooves can be added to facilitate airflow and resin dispersion.

2. Thermoplastic Composite Pressing

Lightweight composite materials require precision heat and pressure to fuse layers properly. CNC machining ensures the press plates support these tight tolerances and delicate materials.

3. Electronics and PCB Production

PCBs require exacting standards in lamination. Any unevenness or overheating can ruin a board. CNC machined plates ensure exact thickness and flatness, critical for high-quality output.

Partnering with the Right Manufacturer

Choosing the right disc or hot press plate manufacturer is just as important as selecting the right material and machining process. Look for companies with deep expertise, advanced CNC equipment, and a commitment to quality assurance.

About Liankun – A Trusted Name in Hot Press Plate Technology

One of the leading players in the CNC machined hot press plate space is Liankun, a globally influential hot platen supplier founded in 2006. Specializing in the production and research of thermal conductive steel platens, Liankun offers a wide variety of hot press solutions tailored to different industries.

Their CNC-machined plates are built with:

Strict flatness and thickness tolerances

Superior thermal conductivity

Durability under long-term high-pressure operation

Flexible mounting options and surface finishes

By leveraging advanced CNC machining technology and a strong commitment to R&D, Liankun delivers plates that meet the most demanding production requirements.

Final Thoughts

CNC machined hot press plates are an essential component in many manufacturing operations. Their precision, durability, and customizability provide a distinct edge in quality and performance. Selecting the right plates, made by a trusted manufacturer with advanced CNC capabilities, can significantly impact the efficiency, sustainability, and profitability of your production line.

Whether you operate in the wood industry, composites, electronics, or beyond, the right hot press plate will always make a difference—and CNC machining ensures you get it right every time.

www.nuknail.com

Kunshan Liankun Hotplaten Co., Ltd.