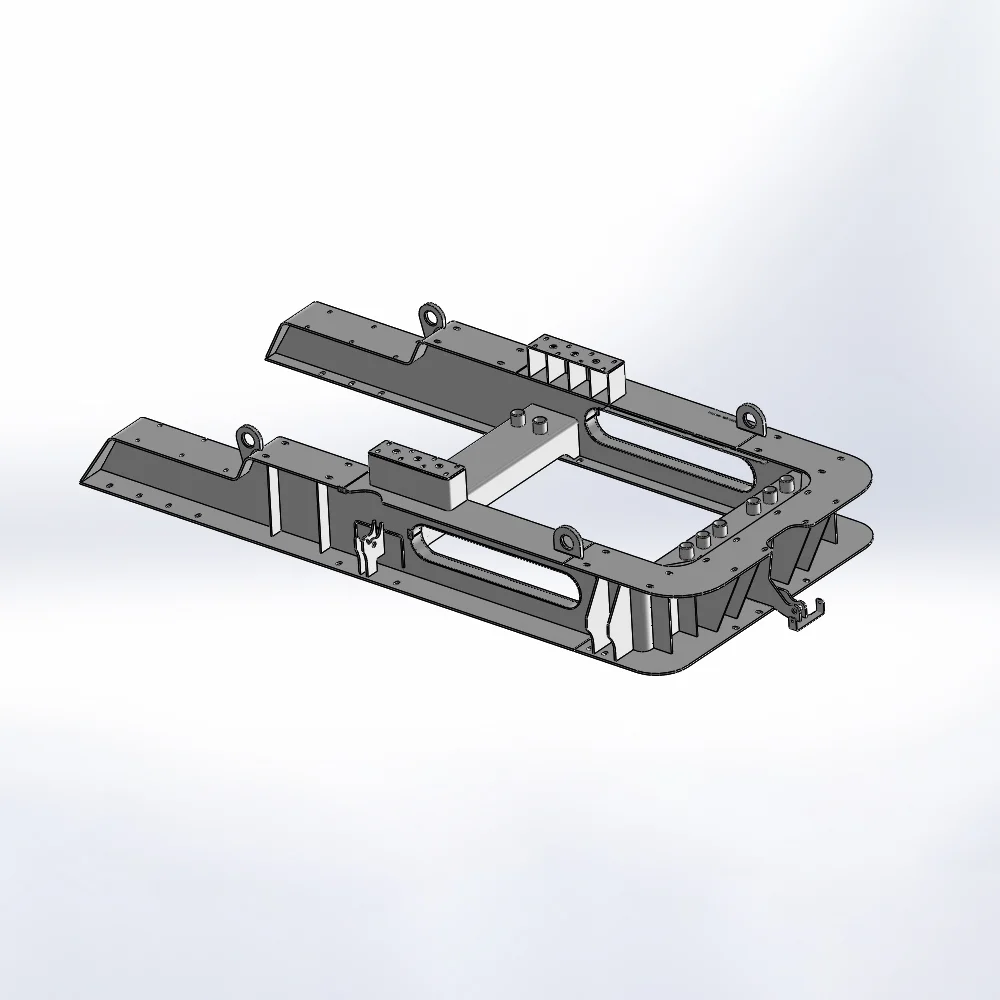

Frame welding fabrication has become the backbone of modern metal manufacturing, particularly for industries such as construction machinery, agricultural machinery, special vehicles, energy, and automotive components. Mastering advanced techniques like laser cutting, robot welding, and CNC machining is essential for achieving high precision, efficiency, and reliability. Hengli, as a leading modern processing enterprise, provides comprehensive solutions across the entire metal supply chain, combining state-of-the-art technology with flexible customization.

Mastering Laser Cutting for Frame Fabrication

Laser cutting is a critical step in achieving precise metal frames. Hengli’s advanced laser systems ensure clean edges, minimal heat-affected zones, and high repeatability. Key advantages include:

-

High Precision: Accurate cuts for complex frame geometries.

-

Efficiency: Faster processing compared to traditional cutting methods.

-

Versatility: Applicable to a wide range of metals and thicknesses.

Robot Welding for Consistent and High-Quality Frames

Robot welding is a game-changer in frame fabrication, providing uniform welds and minimizing human error. Hengli’s automated welding lines offer:

-

Consistency: Identical weld quality across every frame.

-

Speed: Accelerated production without sacrificing accuracy.

-

Durability: Strong, reliable joints for heavy-duty applications.

CNC Machining for Detailed and Complex Components

CNC machining allows precise shaping, drilling, and finishing of frame components. At Hengli, CNC operations are integrated with cutting and welding processes to optimize production workflows. Benefits include:

-

High Accuracy: Components meet exact specifications for fit and function.

-

Flexibility: Ability to handle customized and complex designs.

-

Integration: Seamless connection with laser cutting and robot welding for efficient production.

Hengli’s Integrated Approach to Frame Welding Fabrication

Hengli combines laser cutting, robot welding, and CNC machining into an integrated production chain, enabling:

-

Automation and Digitization: Smart factory processes reduce lead times and improve quality control.

-

Customization: Tailored solutions for clients in construction, agriculture, automotive, and energy sectors.

-

Global Reach: Serving markets across China, North America, and Europe with competitive pricing and high-quality standards.

Conclusion

Mastering laser cutting, robot welding, and CNC machining is key to achieving high-quality frame welding fabrication. Hengli’s integrated approach ensures precision, efficiency, and durability across industries. By leveraging these advanced techniques, manufacturers can enhance productivity, reduce errors, and maintain a competitive edge in the global market.

www.hlmetal.net

Hangzhou Hengli Metal Processing Co.,Ltd.